In many applications where a variety of fluids are handled through complex piping systems, fittings, connections and/or manifold blocks the flow characteristics can be essential to reduce resistance from piping and associated components that control the flow. In many cases the flow calculations may show that large radiuses on internal flow paths would be beneficial in reducing resistance in piping. However, due to the manufacturability simpler flow paths are often utilized. An example of this would be in high pressure systems where forgings are often chosen over castings and due to the limitations of the forging method to produce blanks with more complex internal geometries the design of the component may be limited. This consequently places design engineers in a position where the flow characteristics might need to be sacrificed to be able to produce the component.

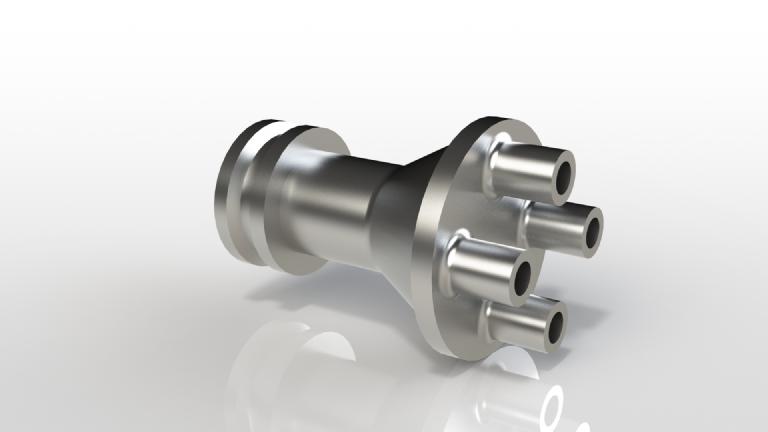

This conflict can be removed when using Powder Metallurgy Near-Net Shape Hot Isostatic Pressing (PM NNS HIP) as the technology offers far more freedom in design when complex internal flow paths can be integrated in the HIP blanks without any need for machining. The below component which is a fitting weighing 2500kg which takes one flow and divides it into four smaller flow paths can be used as an example.

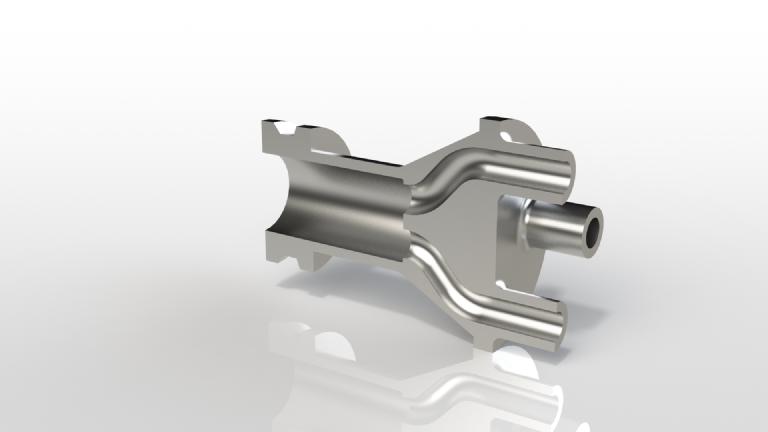

The inside of the component can be seen below and demonstrates how S-shaped flow paths have been integrated in the HIP blank (i.e., condition prior to machining) making it possible to produce geometries that have been optimal in terms of function and flow characteristics and not compromised as a result of the manufacturing method.

The “freedom of design” benefit that PM HIP offers marries well with the material benefits that PM HIP also offers; a 100% isotropic material meaning that all properties of the material are equal in all directions. Therefore, on components produced in HIPed 25Cr Super Duplex materials (UNS 32505) for example, no consideration is needed on material grain directions versus directions of the flow paths which would be needed in a forging design.

Here at MTC Powder Solutions we are invested in understanding where we can help others achieve success and solutions to drive technology forward. From this understanding of PM HIP’s engineering design freedom capabilities, how would your fluid handling components look tomorrow? What products could be redesigned enabling reductions in waste, manufacturing time, and provide the desired solution rather than a compromised solution?