Avoid excessive welding costs

It’s no secret. The welding of complex engineering components is time consuming, costly and a risk. Consider, for example, that a multi-pass weld on a critical subsea component can take up to 20 hours or more to complete. One even took 35 hours for a team of skilled welders! What’s more, poor joint integrity in welded structures can lead to failed X-ray validation, additional rework, greater risk and costly delays.

Reduce or eliminate welding

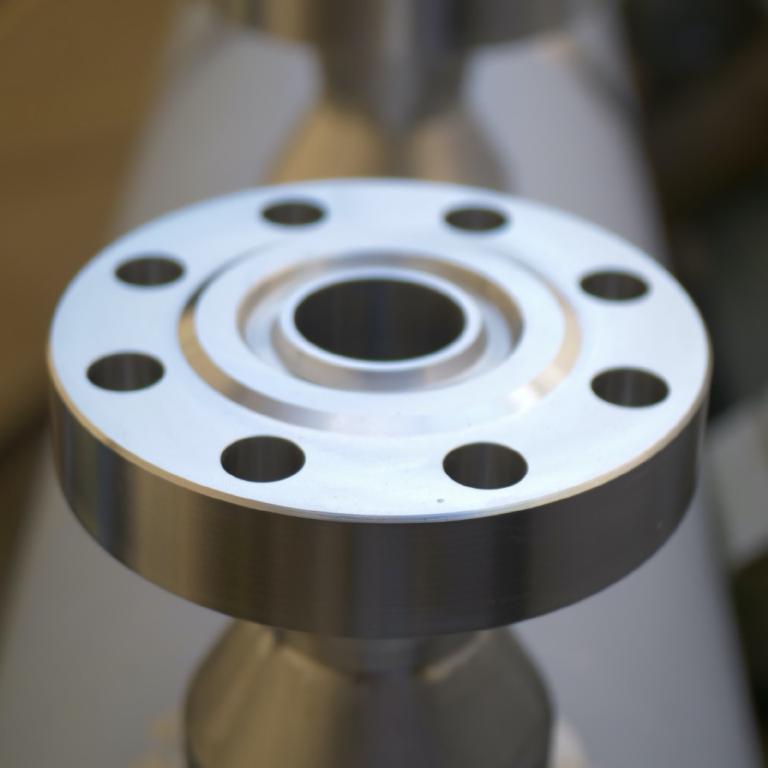

By using the HIP process, components can be designed and fabricated in a way that reduces or completely eliminates welding and, consequently, related inspections and potential weak spots. The need for brazing or welding parts together to form larger structures can be drastically reduced or completely eliminated. This is due to the fact that complex features can be integrated into one seamless component design (e.g. a flange or hub on a valve body).

Avoid weld porosity issues

It’s not uncommon for welds to have small cracks or some porosity in the heat-affected zone (HAZ). This can lead to rejection after radiography and surface dye penetrant inspection. Components fabricated using HIP can eliminate these risks, saving you significant time and money in the process.

HIP VS FORGED: WELDING COST ADVANTAGE*

| Forged product | HIP product | |

|---|---|---|

| Welding time (7 welds x 20 hrs) | 140 hours | 40-60 hours |

| Machining | 50 hours | 10-20 hours |

| Material loss | Approx. 30% | <5% |

| Weight | 5 tons (standard steel) | 3.5 tons (super duplex) |

| Delivery time | 35 weeks | 12-15 weeks |